Product Description

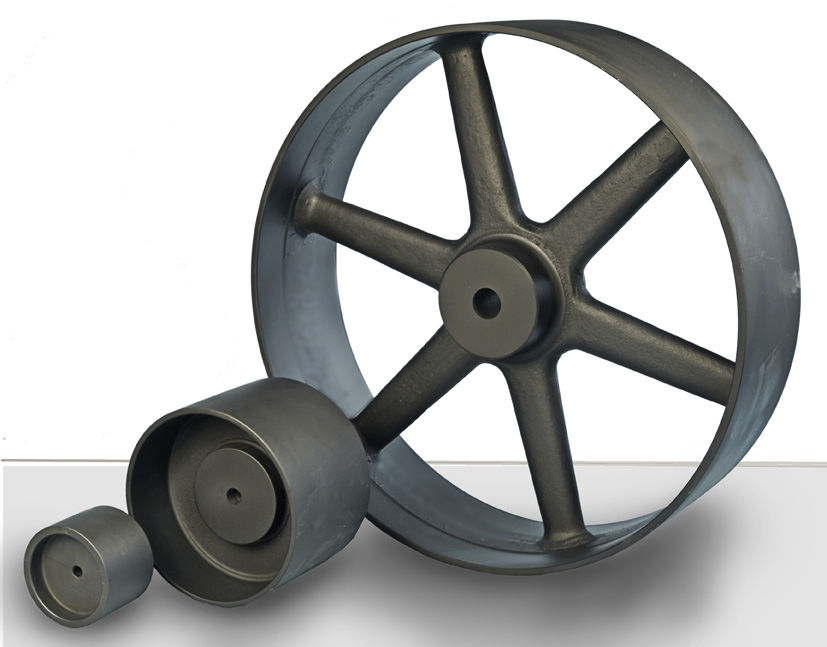

Detailed Photos

Product Description

| Item No. | Door and Window Plastic Bearing Pulley |

| Dimensions | OEM ODM |

| Material | Bearing -Chrome steel, carbon steel, stainless steel Plastic part- POM/ Nylon6 /Nylon66 +GF/PU/Rubber Housing part – Plastic(Nylon)/ Steel/ Zinc alloy die casting / Aluminium profile/ alu. Alloy die casting |

| Color | Original/black/white/Red/ Green/ Orange, or per customers’ requirement |

| Surface Treatment | Zinc plated/Nickle Plated/Black treatment/ Painting/Electrophoretic treatment |

| Features | heavy-duty,adjustable,low noise,easy installation,sliding smoothly,long life,standard,customized,etc. |

| Application | Sliding window and door, Sliding accessories, furniture accessories etc. |

| Packaing | Foil bag+Neutral Carton+Pallet, or per customers’ requirement |

| MOQ | 1000 pcs |

| Lead Time | According to the order q’ty |

| OEM& ODM | Technical drawing or sample is needed |

Company Profile

ABOUT US

Haibite was set up in 1996 and located at HangZhou, a beautiful city in China. Our company is bearing manufacturer&bearing distributor. Since it was first established, CHINAMFG was dedicated in research, development and manufacture of bearings. Now, CHINAMFG has become main and 1 of the first grade suppliers of all kinds of bearings. We could develop the products constructed from different materials, structures, shapes, colors etc.

WELCOME TO THE CLUB!

1. Our rollers are in stable quality with smooth rotation, long life operation, small movement, advanced injection technology engineering etc.

2. The Adjustable Rollers with smooth and long lasting operation, higher performing features like wider adjustment ranges, long rolling life performance, easy installment. It’s available in multiple housing choices with any wheels to fit different aluminnum. Our roller ensure alignment across the full adjustment ranges within built-in retention system.

3. The customized hardware, like plastic parts, stamping patrs, cold forging steel patrs are widely applied in the window and doors, furniture, householders, transmission system, industrial drive system etc.

We are constantly improving and striving for excellent service. We hold a very high regard for our customers, the quality of our products, and our level of customer service.

FAQ

1. who are we?

We are based in ZheJiang , China, start from 2017,sell to North America(1.00%),Africa(1.00%),Western Europe(1.00%),Southern Europe(1.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Bearing cage,Bearing pulley,Plastic products,Miniature bearing,Needle roller bearing

4. why should you buy from us not from other suppliers?

Hardware pulley source factory,20 years professional bearing pulley experience

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW;

Accepted Payment Currency:USD,EUR,JPY,CNY;

Accepted Payment Type: T/T,L/C,D/P D/A;

Language Spoken:English,Chinese,Spanish,Japanese,F

Our Advantages

Sliding glass doors are becoming more and more popular, because of the view and natural lighting that they provide. But there can be some difficulty when it comes to maintaine them, such as the rollers have worn out. The key part is knowing which roller matches the original. Many people believe that alternatives can be found by identifying the door manufacturer individually. Actually, Most rollers are generic and used by various door manufacturers.

As the professional manufacturer of sliding rollers, we use various identifying characteristics to determine the best replacement option for your door. In addition to the number of wheels your roller uses to support the door, the presence of dimples, bumps, cut-outs and flared edges on the rollers housing will narrow down replacement options substantially. The way that the assembly installs in the door frame is also vital. The key dimensions to confirm a replacement include the width and height of the roller’s outer housing, as well as the diameter of the wheel. In addition to the diameter of the wheels, the material that they’re made of, steel or nylon, is also a factor. Long-term, metal wheels are known to hold up better but they can also cause the track to wear out faster, especially on heavy doors. Nylon wheels tend to be kinder to the track but may not last as long as their steel counterparts.

Purchase Notice

1.Pls send us an inquiry or leave us a message, there will be a dedicated staff to serve you within 1 hours.

2.You can ask us to take actual photos of the products for you, and free samples would be provided.

3. Welcome to visit our factory to negotiate orders, we will do our best to protect the safety of your business journey.

4. Packaging can be customized according to customer requirements

Finally, Please be sure to click “Contact supplier” to contact us, or “Call us” with any questions that you may have.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | ISO |

|---|---|

| Manufacturing Process: | Casting |

| Material: | Stainless Steel |

| Samples: |

US$ 0.12/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

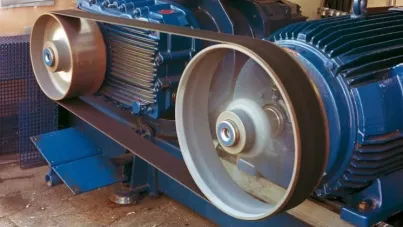

Can flat belt pulleys be integrated into conveyor systems for material handling?

Yes, flat belt pulleys can be effectively integrated into conveyor systems for material handling. Here’s a detailed explanation:

Conveyor systems are widely used in industries for the efficient movement of materials from one location to another. Flat belt pulleys offer several advantages when incorporated into conveyor systems:

1. Power Transmission:

Flat belt pulleys are used as the driving pulleys in conveyor systems. They transmit power from a motor or an engine to the belt, enabling the movement of materials along the conveyor. The large contact area and grip between the pulleys and the belt ensure efficient power transfer, allowing for the transportation of various types of materials.

2. Load Capacity:

Flat belt pulleys are designed to handle different load capacities. They can be selected based on the specific requirements of the conveyor system, such as the weight and type of materials being transported. The pulley’s diameter and width are chosen to provide adequate support and load-bearing capacity for the belt.

3. Belt Tracking:

Proper belt tracking is crucial in conveyor systems to prevent belt misalignment and ensure smooth operation. Flat belt pulleys are designed with features such as flanges or guides to help keep the belt centered and aligned. This ensures that the materials are conveyed along the desired path without any disruptions or spillage.

4. Belt Tensioning and Adjustability:

Flat belt pulleys in conveyor systems are equipped with tensioning mechanisms to maintain the appropriate belt tension. These mechanisms, such as idler pulleys or tensioning screws, allow for easy adjustment of the belt tension to accommodate variations in load or belt stretch over time. Proper tensioning ensures efficient power transmission and prevents belt slippage.

5. Versatility:

Flat belt pulleys offer versatility in conveyor system design. They can be used in straight conveyors, curved conveyors, or inclined conveyors, allowing for the transportation of materials in various directions and angles. The flexibility of flat belts also enables efficient movement around pulleys of different sizes and configurations.

6. Maintenance and Replacement:

Flat belt pulleys in conveyor systems are relatively easy to maintain and replace. Regular inspection and maintenance of the pulleys, including checking for proper alignment and tension, can help prevent issues and ensure efficient operation. When replacement is necessary, flat belts and pulleys are readily available, minimizing downtime and optimizing material handling efficiency.

Consequently, flat belt pulleys are commonly integrated into conveyor systems for material handling due to their efficient power transmission, load capacity, versatility, and ease of maintenance. They are widely used in industries such as manufacturing, warehousing, mining, agriculture, and logistics.

Can flat belt pulleys withstand variations in environmental conditions?

Flat belt pulleys are designed to withstand variations in environmental conditions to a certain extent. Here’s a detailed explanation:

1. Temperature:

Flat belt pulleys can generally tolerate a wide range of temperatures. However, extreme temperatures, either too high or too low, can affect the performance and longevity of the pulleys. High temperatures can cause material expansion, accelerated wear, and deterioration of lubricants, while low temperatures can make materials brittle and increase the risk of cracking or breakage. It’s important to consider the temperature limits specified by the manufacturer and choose materials that can withstand the expected temperature range.

2. Humidity and Moisture:

Flat belt pulleys should be protected from excessive humidity and moisture, as these can lead to corrosion and rust formation, especially in pulleys made of steel or cast iron. Proper sealing, surface treatments, or the use of corrosion-resistant materials can help mitigate the effects of humidity and moisture.

3. Dust and Contaminants:

Accumulation of dust, dirt, or other contaminants on flat belt pulleys can interfere with the belt’s grip, cause slippage, and accelerate wear. Regular cleaning and maintenance are necessary to remove such contaminants and ensure smooth operation.

4. Chemical Exposure:

Flat belt pulleys may encounter various chemicals depending on the application. Some chemicals can degrade the materials used in the pulleys, leading to reduced strength, increased wear, and failure. It’s important to select materials that are resistant to the specific chemicals present in the environment.

5. UV Exposure:

Exposure to ultraviolet (UV) radiation from sunlight or certain artificial sources can degrade the properties of pulley materials, particularly plastic components. UV-resistant coatings or selecting materials with inherent UV resistance can help mitigate the effects of prolonged UV exposure.

6. Vibrations and Shock:

Flat belt pulleys should be designed to withstand vibrations and shock loads that may be present in the operating environment. Excessive vibrations or shocks can lead to misalignment, increased wear, and premature failure. Proper installation, alignment, and the use of vibration-damping materials can help minimize these effects.

While flat belt pulleys can tolerate variations in environmental conditions, it’s important to assess the specific operating environment and select pulleys and materials accordingly. Adhering to manufacturer guidelines, performing regular inspections, and implementing appropriate maintenance practices can help ensure the longevity and reliable performance of flat belt pulleys in various environmental conditions.

What advantages do flat belt pulleys offer for power transmission?

Flat belt pulleys offer several advantages for power transmission in various applications. Here’s a detailed explanation:

1. Simplicity:

Flat belt pulley systems are relatively simple in design and operation. They consist of a pulley and a flat belt, which are easy to install, maintain, and replace. The simplicity of the system makes it accessible and user-friendly, requiring minimal training or expertise to operate and maintain.

2. Cost-effectiveness:

Flat belt pulley systems are often cost-effective compared to other power transmission systems. The components, such as the pulleys and belts, are generally affordable and readily available. Additionally, the installation and maintenance costs are typically lower compared to more complex systems, making flat belt pulleys a cost-efficient choice for power transmission in certain applications.

3. High Speed Capability:

Flat belt pulleys can operate at high speeds, making them suitable for applications that require rapid power transmission. The flat belt design allows for smooth and efficient power transfer, reducing the risk of slippage or loss of power even at high rotational speeds.

4. Shock Absorption:

Flat belt pulleys offer good shock absorption properties due to the flexibility of the flat belt. The belt can absorb and dampen sudden shocks or vibrations, protecting the pulley system and the connected components from damage. This is particularly advantageous in applications where the machinery may experience variable or intermittent loads.

5. Compatibility:

Flat belt pulleys are compatible with a wide range of machinery and equipment. They can be easily integrated into existing systems without requiring significant modifications or adaptations. This compatibility makes flat belt pulleys a versatile choice for power transmission in various industries.

6. Misalignment Tolerance:

Flat belt pulleys can tolerate slight misalignments between the driving and driven shafts. The flexibility of the flat belt allows for some degree of deviation in alignment without affecting the overall performance or causing excessive wear on the components. This tolerance to misalignment can be beneficial in applications where precise alignment is challenging to achieve or maintain.

7. Smooth and Quiet Operation:

Flat belt pulleys provide smooth and quiet operation, contributing to a more comfortable and less noisy working environment. The flat belt design reduces vibrations and noise generated during power transmission, resulting in smoother machinery operation and reduced noise pollution.

8. Energy Efficiency:

The efficiency of power transmission in flat belt pulley systems can be quite high. With proper tensioning and adequate belt grip on the pulley, the system minimizes energy losses due to slippage or friction. This energy efficiency can lead to cost savings and improved overall equipment performance.

In summary, flat belt pulleys offer advantages such as simplicity, cost-effectiveness, high-speed capability, shock absorption, compatibility, misalignment tolerance, smooth and quiet operation, as well as energy efficiency. These advantages make flat belt pulleys suitable for various applications where these characteristics are desired or required.

editor by CX

2024-04-26