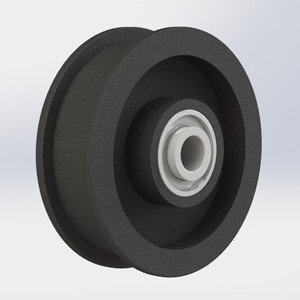

Product Description

>> If you receive quality problems with the product, please contact us in time and handle it properly for you.

>> You need to provide teeth profile, teeth quantity, belt width, bore diameter, quantity and type. Please send us drawings to get our best quotation.Thanks

| Product name | Belt pulley / Timing pulley | |

| Teeth profile | Arc toothed | HTD3M, HTD5M, HTD8M, HTD14M, HTD20M, Gt2, Gt3, Gt5 |

| Arc Gt toothed | Gt2,Gt3,Gt5 | |

| Trapezoidal toothed | MXL, XXL, XL, L, H, XH, XXH | |

| T-toothed | T2.5, T5, T10, T20 | |

| AT-toothed | AT3,AT5,AT10,AT20 | |

| S-toothed | S2M, S3M, S4.5M, S5M, S8M, S14M | |

| Parabolic-toothed | P2M, P3M, P5M, P8M, P14M | |

| Y-toothed | G2M, G3M, G5M, Y8M | |

| Teeth Quantity | 10-150 teeth or customized | |

| Inner Bore | 2-200mm H7 precision or customized | |

| materials | Carbon steel, aluminum alloy frequently used, brass and cast iron available. | |

| Surface treatment | Anodize, Black Oxide, Phosphate and Galvanization. | |

| Specification | OEM serice, strictly according drawing and samples | |

| Application | Machining, Mining Accessories, Machinery Accessoried, Truck Parts, Auto Parts, Industrial Parts, etc | |

| FEATURE#1 – Accurate transmission – Balance – Low noise – No slip |

|

| FEATURE#2 – Multi-axis transmission – Oil resistant – Moisture proof – No lubication required |

|

| FEATURE#3 – Safety & Eco-friendly – Wide range of applications – Support customization |

HangZhou CHINAMFG Rubber & Plastic Co.,Ltd

Established in 2008, Is a Specializing in the production of agricultural/industrial machinery parts, currently producing timing belts, conveyor belts, crawlers, synchronous wheels, gears, bearings, engines and other spare parts. Our products are SGS, RoHS, M1 and UL certified,Our factory is located in Zhangting Industrial Zone, Xihu (West Lake) Dis., HangZhou, which is only 50 kilometers away from the famous HangZhou Port (Harbor). covers an area of 9,000 square meters, with 6,000 square meters’ standard workshops and world-class equipment, we have exported our products to many international markets including the UK, Southeast Asia, France, Australia, Canada, etc.Please feel free to contact us for more information.

==================================== FAQ ======================================

1) Q: I haven’t done business with you before, how can i trust your company?

A: Our company are made-in-china CHINAMFG supplier and passed Field certification by made-in-china. What’s more,we’ve got authority certificates for ISO9001.

2) Q: How is quality ensured?

A: All our processes strictly adhere to ISO9001:2008 procedures, we have strict quality control from producing to delivery,100% inspection by professional testing centre. Small samples could be provided to you for testing.

3) Q: Can i get 1 or more samples?

A: Yes, sample orders welcomed.

4) Q: Do you give any discounts?

A: Yes, we’ll surely try my best to help you get the best price and best service at the same time.

5) Q: How to Custom-made(OEM/ODM)?

A: Please send you product drawings or samples to us if you have, and we can custom-made as you requirements.We will also provide professional advices of the products to make the design to be maximize the performance. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO |

|---|---|

| Manufacturing Process: | Hobbing |

| Material: | C45#Steel,Brass,Aluminum, POM |

| Surface Treatment: | Baking Paint |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant, Industrial Agricultural Machinery |

| Name: | Timing Pulley |

| Samples: |

US$ 30/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What is the importance of proper pulley alignment and tensioning in flat belt pulley systems?

Proper pulley alignment and tensioning are crucial in flat belt pulley systems. Here’s a detailed explanation:

1. Efficient Power Transmission:

Proper pulley alignment and tensioning ensure efficient power transmission in flat belt pulley systems. When the pulleys are correctly aligned, the belt remains centered on the pulley surfaces, minimizing friction and reducing energy losses. Additionally, maintaining the appropriate tension in the belt prevents slipping and ensures optimal power transfer from the driving pulley to the driven pulley, maximizing the efficiency of the system.

2. Belt Longevity:

Correct pulley alignment and tensioning contribute to the longevity of flat belts. Improper alignment can cause the belt to rub against the pulley edges, leading to accelerated wear and tear. Similarly, insufficient tension or excessive tension can cause excessive stretching or strain on the belt, reducing its lifespan. By aligning the pulleys properly and maintaining the recommended tension, the belt experiences minimal stress and wear, prolonging its durability.

3. Reduced Noise and Vibration:

Proper pulley alignment and tensioning help minimize noise and vibration in flat belt pulley systems. Misaligned pulleys can create uneven forces, causing the belt to generate noise and vibrations during operation. These vibrations can propagate through the system, affecting other components and potentially leading to increased wear and reduced overall system performance. By ensuring proper alignment and tensioning, the system operates smoothly, reducing noise and vibration levels.

4. Prevent Belt Slippage:

Correct tensioning in flat belt pulley systems prevents belt slippage, ensuring reliable operation. Insufficient tension can cause the belt to slip on the pulleys, resulting in a loss of power transmission and compromised system performance. Proper tensioning ensures that the belt maintains sufficient grip on the pulley surfaces, preventing slippage and ensuring consistent power transfer.

5. Accurate Speed Control:

Proper pulley alignment and tensioning enable accurate speed control in flat belt pulley systems. When the pulleys are aligned correctly, the belt operates with consistent tension, allowing for precise speed control of the driven pulley. This is important in applications where specific speeds are required for tasks such as material handling, machining, or processing. Accurate speed control helps maintain product quality, prevents damage to equipment or materials, and ensures efficient operation.

6. Improved Safety:

Ensuring proper pulley alignment and tensioning enhances safety in flat belt pulley systems. Misaligned or poorly tensioned belts can pose a safety hazard as they may come off the pulleys or cause unexpected system failures. By aligning the pulleys correctly and maintaining the recommended tension, the risk of belt dislodgement or sudden system failures is minimized, promoting a safer working environment for operators.

7. Optimal System Performance:

Ultimately, proper pulley alignment and tensioning contribute to the overall performance of flat belt pulley systems. By maintaining the belts in the correct position on the pulleys and ensuring proper tension, the system operates at its intended capacity, delivering consistent power transmission, reliable operation, and efficient performance. This helps maximize productivity, reduce downtime, and optimize the lifespan of the components within the system.

In conclusion, proper pulley alignment and tensioning are vital for efficient power transmission, belt longevity, reduced noise and vibration, prevention of belt slippage, accurate speed control, improved safety, and optimal performance in flat belt pulley systems.

Can flat belt pulleys be customized for specific machinery and equipment?

Yes, flat belt pulleys can be customized to suit specific machinery and equipment requirements. Here’s a detailed explanation:

1. Pulley Dimensions:

Flat belt pulleys can be customized in terms of their dimensions to fit the specific space and clearance constraints of the machinery or equipment. The outer diameter, inner diameter, and width of the pulley can be adjusted to ensure proper alignment and fit within the system.

2. Shaft Compatibility:

Customized flat belt pulleys can be designed to match the shaft size and configuration of the machinery or equipment. This ensures a secure and accurate connection between the pulley and the shaft, minimizing any potential slippage or misalignment issues.

3. Material Selection:

The choice of material for the pulley can be customized based on the specific requirements of the machinery or equipment. Different materials, such as steel, aluminum, or plastic, offer varying levels of strength, durability, and corrosion resistance. The material selection can be tailored to suit factors such as the operating environment, load capacity, and desired longevity of the pulley.

4. Keyways and Set Screw Holes:

Customized flat belt pulleys can be manufactured with keyways or set screw holes to enhance the connection and torque transfer between the pulley and the shaft. Keyways provide a positive locking mechanism, preventing rotational slippage, while set screw holes allow for secure fastening using set screws.

5. Surface Coatings:

In certain cases, customized flat belt pulleys can be coated or treated with specific surface finishes or coatings. These coatings can provide benefits such as improved wear resistance, reduced friction, or enhanced corrosion protection, depending on the operating conditions and requirements of the machinery or equipment.

6. Special Features:

Customized flat belt pulleys can incorporate special features or modifications based on the unique needs of the machinery or equipment. This may include additional mounting holes, balancing adjustments, or specific groove profiles to accommodate different belt types or configurations.

By working with pulley manufacturers or suppliers, machinery or equipment manufacturers can collaborate to design and produce customized flat belt pulleys that precisely meet the requirements of their specific applications.

It’s important to note that the customization process will depend on factors such as the complexity of the pulley design, production feasibility, and any minimum order quantities that may be required by the manufacturer.

How do flat belt pulleys differ from other types of pulleys?

Flat belt pulleys have distinct characteristics that set them apart from other types of pulleys. Here’s a detailed explanation:

1. Belt Type:

The major difference lies in the type of belt used. Flat belt pulleys are specifically designed to work with flat belts, which are flexible and have a rectangular cross-section. In contrast, other types of pulleys, such as V-belt pulleys or timing belt pulleys, are designed for different belt profiles, such as V-shaped belts or toothed belts.

2. Belt Engagement:

Flat belt pulleys engage with the belt differently compared to other pulley types. The flat belt wraps around the pulley’s flat or slightly concave surface and relies on friction to transmit power. Other pulley types, like V-belt pulleys, have grooves that match the shape of the belt, providing positive engagement by fitting into the belt’s grooves.

3. Power Transmission:

Each pulley type is optimized for specific power transmission requirements. Flat belt pulleys are often used for applications that require relatively low power and moderate speeds. They are suitable for machinery that needs flexibility and ease of installation, making them commonly used in older machinery and certain industrial applications. Other pulley types, like V-belt pulleys or timing belt pulleys, offer advantages for high-power transmission, increased efficiency, or precise timing in applications such as automotive engines or industrial machinery.

4. Pulley Design:

Flat belt pulleys have a simple design, typically consisting of a cylindrical or disk-shaped body with a flat or slightly concave surface. Other pulley types may have more complex designs to accommodate specific belt profiles. For example, V-belt pulleys have grooves that match the V-shaped belts, while timing belt pulleys have toothed profiles that match the teeth on the timing belts.

5. Speed and Torque Conversion:

The design and configuration of pulleys, including flat belt pulleys, allow for speed and torque conversion. By varying the sizes of the pulleys, the speed and torque can be adjusted to meet the requirements of the machinery. However, the specific mechanisms for speed and torque conversion may differ between pulley types. For example, V-belt pulleys rely on the varying diameters of the pulleys to achieve speed conversion, while timing belt pulleys use the toothed profiles to ensure precise timing and synchronization.

6. Belt Tension and Alignment:

The methods used to maintain belt tension and alignment can also differ between pulley types. Flat belt pulleys often rely on adjustable pulley positions or tensioning mechanisms to achieve proper tension and alignment. Other pulley types may incorporate features like automatic tensioners or specialized tensioning systems to maintain optimal belt performance.

In conclusion, flat belt pulleys differ from other types of pulleys in terms of the belt type, engagement method, power transmission capabilities, design, speed and torque conversion mechanisms, as well as belt tension and alignment methods. Understanding these differences is crucial for selecting the appropriate pulley type for a given application.

editor by CX

2024-04-25